Here's a few pics of the finishing. That could be a whole book on its own so I won't bother to talk too much about it and just state what I did.

I started by shooting several coats of clear lacquer to fill the pores of the ash and let it fill up, sanded that flat then shot a coat of amber on the body. After the amber coat I shot 2 coats of clear on top of that. The coats of clear are to lock in the amber colour and give it a bit of protection when sanding the body so I don't sand through the colour.

This pic just shows the body after in the raw after masking it before its first coat

Once I had the clear and amber I then shot the dark edge of the sunburst whihc is a medium brown colour mixed with some black in it, it looks pretty black on pictures and in person but if you're in the sun outside, you can see its brown and can see through it to the wood.

Once you shoot the black edge, you need to shoot a few coatgs of clear too to lock the colour in and prevent sanding through it. Finally you shoot the red band on the body then two coats of clear to lock it in then the day after sand it down and shoot another 5 or 6 coats of clear to buildup the clear, in the end we've got our 3 tone burst.

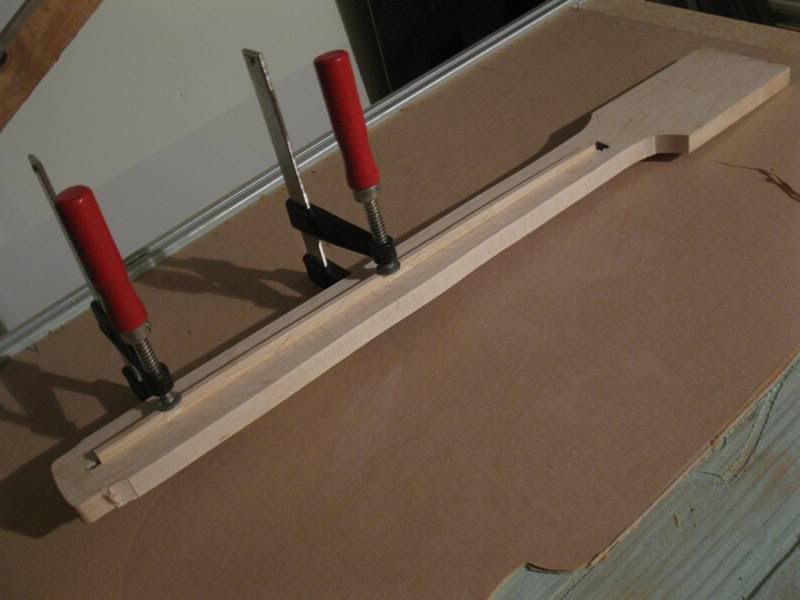

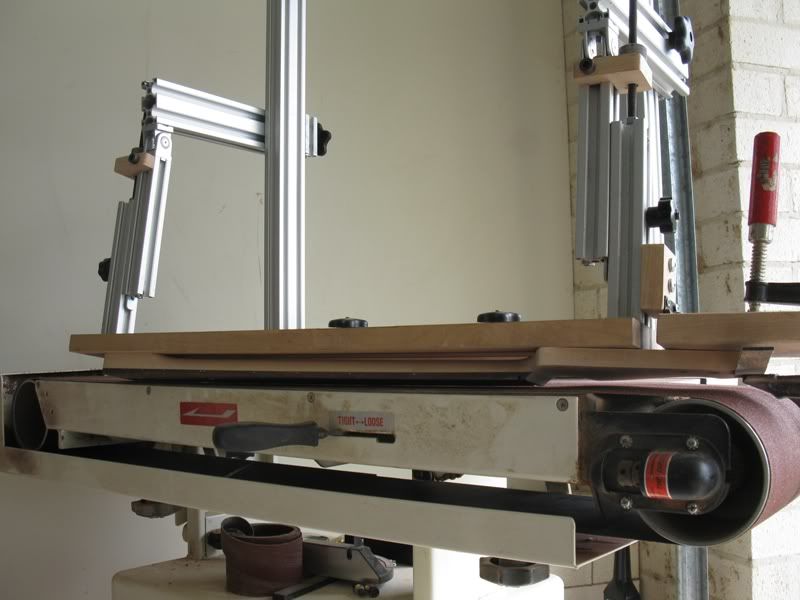

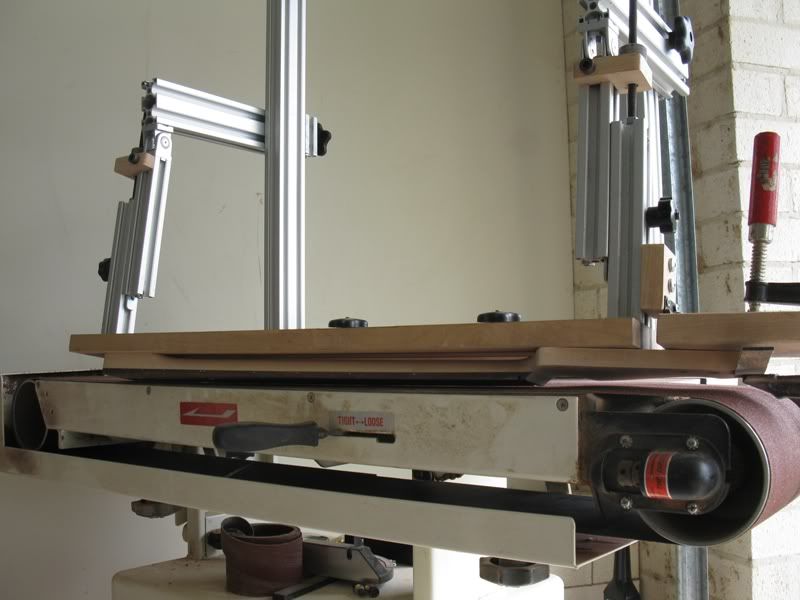

The fingerboard radius has recently become a fun job with the radius sanding jig I built. All the knobs on the arms are to adjust the height of them. With this I can do radiuses from about 7" until about 20"

I tape the neck with double sticky tape under the jig then rock the neck back and forth on the sander for a minute and the radius comes out all ready to go.

Next up is the fretwork

The fretwire has been cut to size and placed in order in that block of wood with the holes drilled in it. thats for making sure I use the right frets at the right place. The frets are all cut almost flush to the fingerboard to save on material.

That fantastic tool is a tang cutter, its great and makes a tiresome job easy and fast, well worth its cost.

I cut the tangs on my necks as I don't like the look of them on the side of the fretboard. I also had a neck on a guitar years ago that used to shrink and expand depending on the weather. In the summer the tangs came out of the neck at the egde and would cut me all the time. This prevents that.

Tap the frets in the fretslot at both ends just to let them sit in the slots. The wire is always a smaller radius to the fingerboard to help push the wire in the slots and push the tangs inside the wood on the edges of the slot to help anchor them inside.

Once tapped in, press the frets into place.

Next step is to glue the frets in. I clamp them on a 12" radius sanding beam, this assures the frets are all in properly and all flat then I put a drop of hot stuff cyanoacrylate (super glue) in the fret slot at both sides and let it sit for a minute, the fret is then glued in solid in there.

Cut off the leftover bits of fret wire

Take the angled file and shave the fret ends at an even angle along the length of the neck

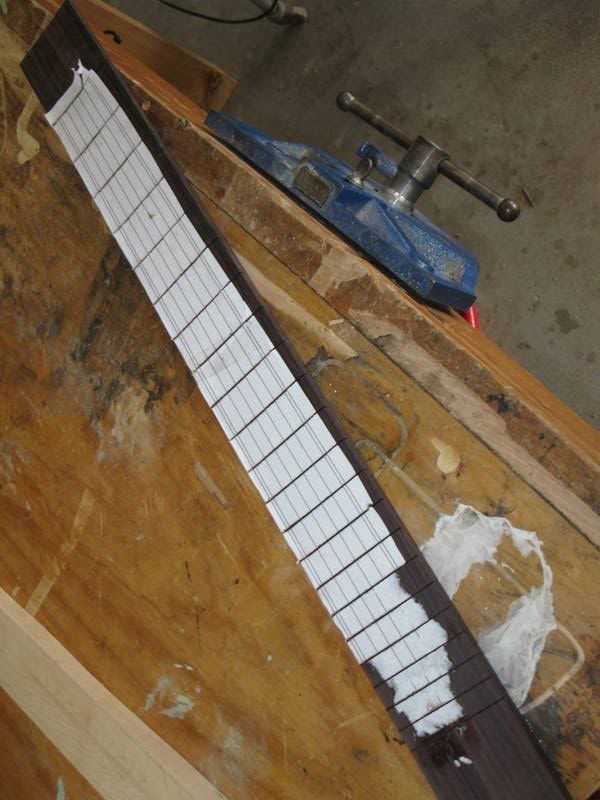

As you can see there's holes in the sides of the fretboard since we cut the tangs shorter...

Take an offcut from the fingerboard and file it until you get a lot of dust from it, mix it with wood glue into a thick paste.

and squeeze it into the slots

After half an hour you can sand it flat. You do end up with really sharp edges from filing the fret ends though

So grab your fret end file and round off the edges of the frets so they're all nice and smooth to the feel

The next step is to mask off the fingerboard and then spray it, that'll be for another day.